-

Module 2.0 How to be Successful in this Course

-

Module 2.1 Introduction to Natural Gas

-

Module 2.2 The Natural Gas Industry in British Columbia

- Overview

- Learning Outcomes

- Natural Gas Science – The Simple Version

- Natural Gas Science – Chemistry

- Natural Gas Science – Physics

- Natural Gas Science – Units of Measurement

- Natural Gas Science – Geology

- Natural Gas Resources and Uses

- Oversight of the Natural Gas Industry

- Understanding Land Rights and Natural Gas

- Energy and the Future

-

Module 2.3 Upstream – Well Site Selection, Preparation and Drilling, Completion, Production, Water Recycling, and Reclamation

- Learning Outcomes

- The Upstream Sector – Extraction and Processing

- The Upstream Sector – Exploration and Site Selection

- The Upstream Sector – Preparation and Drilling

- The Upstream Sector – Completion

- The Upstream Sector – Production

- The Upstream Sector – Water Recycling

- The Upstream Sector – Reclamation

- Upstream Companies and Jobs in British Columbia – Companies

- Upstream Companies and Jobs in British Columbia – Industry Associations

- Upstream Companies and Jobs in British Columbia – Professional Associations

- New Vocabulary

-

Module 2.4 Midstream – Transportation, Processing, Refining

- Learning Outcomes

- The Midstream Sector

- The Midstream Sector – Processing Natural Gas

- The Midstream Sector – Liquefied Natural Gas

- The Midstream Sector – An Emerging Industry

- The Midstream Sector – Processing LNG

- The Midstream Sector – Proposed LNG Projects in British Columbia

- Transportation

- Midstream Companies and Jobs in British Columbia

-

Module 2.5 Downstream – Refining and Markets

-

Module 2.6 Health and Wellness in the Natural Gas Industry

-

Module 2.7 Safety

-

Module 2.8 Terminology and Communication

-

Module 2.9 Jobs and Careers

- Learning Outcomes

- Industry Outlook

- Technology is Changing Workforce and Skills

- Employment in the Natural Gas Industry

- Employment in the Natural Gas Industry – Types of Employment

- Employment in the Natural Gas Industry – Range of Jobs

- Employment in the Natural Gas Industry – High Demand Jobs and Occupations

- Occupational Education and Training

-

Module 3.0 How to be a Valued Employee

-

Module 3.1 Identifying Interests and Skills

-

Module 3.2 Looking for Employment in Natural Gas

-

Module 3.3 Applying for Employment in Natural Gas

Refining

Despite being termed as “natural” gas, you now know that natural gas straight from the ground is processed, pressurized, and transported in pipelines, first by the upstream sector of the industry and then again (for different purposes) by the midstream sector. The downstream sector is where the final stage of processing happens—refining natural gas from the midstream sector for commercial, industrial, and residential use.

Refined natural gas and its derived products must be transported and stored for distribution and sale much in the same way as natural gas and related products are in the upstream and midstream sectors. This involves similar logistics and methods (including pipelines and land/marine shipping), as are discussed in module 2.3. For this reason, transportation and storage are not discussed in this module.

Natural gas products produced in the downstream sector of the industry play a major role in industries and areas of our lives, some which you are likely familiar with, while others may be more of a mystery. For example, you know (hopefully by now!) that natural gas is used as a fuel/heat source in many industries e.g., transportation, agriculture, glass, automotive, and many other energy-dependent industries.

What may be less obvious, are products we use daily where it is no longer obvious that natural gas is even an ingredient.

Refined Natural Gas Products

Products created in the downstream sector are commonly used by Canadian households, businesses, and industries almost daily. Without their ready availability, our quality of life would be drastically different.

Products created in the downstream sector are commonly used by Canadian households, businesses, and industries almost daily. Without their ready availability, our quality of life would be drastically different.

The following sections provide examples of some of these products.

Fuel for Motor Vehicles – NGV

Natural gas is used as a motor fuel for conventional vehicles (cars, busses, trucks, ferries), commercial transport vehicles (water, air, land, and rail-based), and industrial vehicles and equipment. When refined into compressed (or pressurized) methane, natural gas fuel:

- costs half as much as gasoline with the octane number of 76

- extends the service life of an engine

- is low density (20% lighter than jet fuel)

- is easier on urban ecology.

Natural Gas Separation

Primary gas processing takes place at gas processing plants, referred to as GPPs. In addition to methane, natural gas contains different things that must be separated out. These elements are nitrogen, carbon dioxide, hydrogen sulphide, helium, and water vapours.

GPPs first clean and dry the natural gas. Then the gas is compressed to a pressure required for processing by gasoline extraction units. Gas extraction units separate the gas into unstable natural gas and lean gas. The lean gas is pumped into gas trunk lines and sent to chemical plants to make methanol and ammonia.

Unstable gas is supplied to gas fractionation units which extract light hydrocarbons to produce products such as: ethane, propane, butane, and pentane, each of which has its own market. In turn, these products become feedstock for further processing. For example, polymers and rubbers are subsequently produced from them. The propane-butane mixture is a finished product by itself which is pumped into cylinders and used as a household fuel.

Paint, Glue and Vinegar

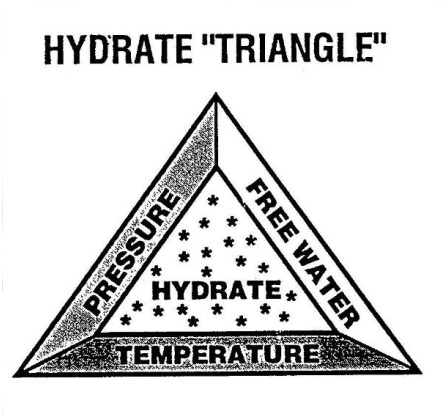

Methanol is produced from natural gas. Methanol is used as an agent for preventing hydrate plugs that can form in pipelines at low temperatures.

Methanol is also an ingredient in more complex chemical substances such as: formaldehyde, insulation materials, varnishes, paints, glues, fuel additives, and acetic acid.

Mineral Fertilizers

Mineral fertilizers are produced from natural gas by means of several chemical conversions. In its first stage it is ammonia. The process to produce ammonia is similar to that used to change gas-to-liquid; the differences are in the required catalysts, pressure, and temperature.

Ammonia is a fertilizer; it is also used as a coolant in refrigerating units and as a feedstock to produce nitrogen compounds, such as nitric acid, ammonia nitrate, and carbamide (also known as urea).

|

A hydrate plug is… Hydrates are a mixture of water and gas molecules that crystallize to form a solid “ice plug” under appropriate conditions of temperature and pressure. Hydrates can form from free water condensed in the gas stream at or below its water dew point. Hydrate formation will not occur if any one of the three required elements symbolized below are altered. Hydrates can form in any segment of an operating system:

|

Source: Canadian Association of Petroleum Producers, |

Plastics

In addition to providing fuel to industry and for home heating, natural gas is used to make plastics such as polyethylene and polypropylene which are then used to make material for clothing, electronics, medical equipment, automobile parts, and a host of other items.