-

Module 2.0 How to be Successful in this Course

-

Module 2.1 Introduction to Natural Gas

-

Module 2.2 The Natural Gas Industry in British Columbia

- Overview

- Learning Outcomes

- Natural Gas Science – The Simple Version

- Natural Gas Science – Chemistry

- Natural Gas Science – Physics

- Natural Gas Science – Units of Measurement

- Natural Gas Science – Geology

- Natural Gas Resources and Uses

- Oversight of the Natural Gas Industry

- Understanding Land Rights and Natural Gas

- Energy and the Future

-

Module 2.3 Upstream – Well Site Selection, Preparation and Drilling, Completion, Production, Water Recycling, and Reclamation

- Learning Outcomes

- The Upstream Sector – Extraction and Processing

- The Upstream Sector – Exploration and Site Selection

- The Upstream Sector – Preparation and Drilling

- The Upstream Sector – Completion

- The Upstream Sector – Production

- The Upstream Sector – Water Recycling

- The Upstream Sector – Reclamation

- Upstream Companies and Jobs in British Columbia – Companies

- Upstream Companies and Jobs in British Columbia – Industry Associations

- Upstream Companies and Jobs in British Columbia – Professional Associations

- New Vocabulary

-

Module 2.4 Midstream – Transportation, Processing, Refining

- Learning Outcomes

- The Midstream Sector

- The Midstream Sector – Processing Natural Gas

- The Midstream Sector – Liquefied Natural Gas

- The Midstream Sector – An Emerging Industry

- The Midstream Sector – Processing LNG

- The Midstream Sector – Proposed LNG Projects in British Columbia

- Transportation

- Midstream Companies and Jobs in British Columbia

-

Module 2.5 Downstream – Refining and Markets

-

Module 2.6 Health and Wellness in the Natural Gas Industry

-

Module 2.7 Safety

-

Module 2.8 Terminology and Communication

-

Module 2.9 Jobs and Careers

- Learning Outcomes

- Industry Outlook

- Technology is Changing Workforce and Skills

- Employment in the Natural Gas Industry

- Employment in the Natural Gas Industry – Types of Employment

- Employment in the Natural Gas Industry – Range of Jobs

- Employment in the Natural Gas Industry – High Demand Jobs and Occupations

- Occupational Education and Training

-

Module 3.0 How to be a Valued Employee

-

Module 3.1 Identifying Interests and Skills

-

Module 3.2 Looking for Employment in Natural Gas

-

Module 3.3 Applying for Employment in Natural Gas

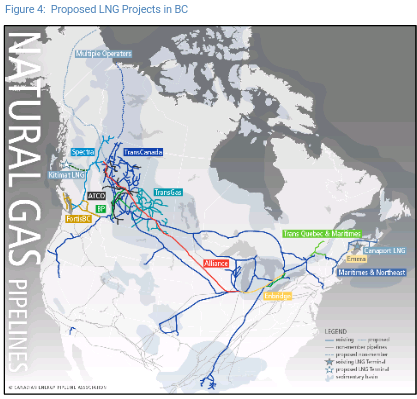

Gas Pipelines

All the natural gas production in Canada is transported to processing facilities and eventually to sales markets through pipelines. Figure 4 shows Canada’s Existing and Proposed Natural Gas Pipelines.

All the natural gas production in Canada is transported to processing facilities and eventually to sales markets through pipelines. Figure 4 shows Canada’s Existing and Proposed Natural Gas Pipelines.

Pipelines serving wells and facilities in the upstream natural gas sector are referred to as flow lines or gathering systems. Companies operate more than 200,000 kilometres of flow lines and gathering systems in the natural gas producing areas of western Canada. These are relatively small pipelines; between 50 to 600 millimetres in diameter. About 60 per cent of the gathering lines carry natural gas and natural gas liquids.

Canada’s natural gas pipeline system is highly interconnected with the U.S. pipeline system. TC Energy operates the largest network of natural gas pipelines in North America, including thirteen major pipeline systems and more than 60,000 kilometres of gas pipelines in operation.

- TC Energy operates more than 42,000-kilometre network that includes the 10.6 billion cubic feet per day (bcf/d) Alberta System and the 7.2 bcf/d Canadian Mainline

- Enbridge Energy operates more than 5,700 kilometres, 2.2 bcf/d pipeline system connecting western Canadian gas supply regions with markets in the U.S. and Canada. Spectra Energy also operates the Maritimes and Northeast Pipeline linking eastern Canadian supplies with consumers in the eastern United States.

- Alliance Pipeline operates a 3,720-kilometre system, which is a significant source of natural gas for the U.S. Midwest and delivers 4.6 bcf/d to both Canadian and U.S. markets.

Pipeline Considerations

There are many considerations that need to be addressed in building and operating pipelines to transport natural gas. This is because the gas often has to travel tremendous distances to reach the end-user or consumer. Some of the most common considerations include:

Compressor Stations

Getting the natural gas to travel the long distances through the pipeline to LNG facilities and gas distribution locations requires extreme amounts of compression. Even with high amounts of pressure, pipeline routes need compression at specific intervals to keep the flow moving. Natural gas compressor stations occur at 65-160 km intervals to maintain consistent pressure.

Geopolitical

Since natural gas travels so far, pipelines are at times required to pass through communities and cross provincial, national, or even international boundaries. To ensure protection of Aboriginal rights, public safety and preserve the environment, government, Indigenous communities, and other landowners or jurisdictional organizations in these areas set regulations and specify conditions that must be satisfied by companies prior to building and while operating a pipeline. Some examples include permits, licenses, royalty payments, consultations, and more.

Indigenous Consultation

Project impacts to Aboriginal rights and title are a priority consideration when contemplating natural gas projects in Canada. Government and Industry proponents are working to enhance their approach to Indigenous consultation and better collaboration with Indigenous peoples into the pipeline planning and development process. Efforts to advance this objective include working with industry and key federal and provincial agencies and other partners to enhance consultation with Indigenous communities on pre-engagement, project planning, development, monitoring, incident response, and general pipeline and environmental safety. Once Free Prior and Informed Consent has been achieved with impacted Indigenous communities, then project construction can be started once regulatory approval has been received

Terrain and Weather

A natural gas pipeline travels across a wide variety of different terrains and must withstand a multitude of weather conditions. For instance, it may begin its journey in northern British Columbia, but need to travel across mountainous, heavily forested, or environmentally sensitive regions. Temperature conditions can range from severely cold to extremely hot and be accompanied by snow, rain, and wind. This wide variety of terrain and weather conditions requires specialized knowledge not only of building and maintenance techniques, but also of how the techniques and materials used perform and withstand conditions over time

Maintenance

Maintenance of natural gas pipelines is critically important. The key challenge is to prevent the pipes from cracking or bursting, something that is made even more difficult by terrain and weather conditions.

The incentives for proper maintenance are significant:

- Damaged pipelines are expensive to repair and may interfere with the ability to meet supply and demand requirements.

- The potential damage that may occur from an improperly maintained natural gas pipeline could be very harmful to people, property, or the environment.

Video5: TransCanada Pipeline Safety and Integrity Inline Inspection (3 minutes, 59 seconds)

Table 2: BC Pipeline Performance Per KM in 2018

|

Total Number of incidents With Release Per 1,000 km by Type of Pipeline in 2018 |

|||

|

Type of Pipeline |

# of Incidents with Release |

Length of Pipeline (km) |

Frequency |

|

Sour Natural Gas |

1 |

15,056 |

0.07 |

|

Natural Gas |

6 |

21,831 |

0.27 |

|

Liquid Hydrocarbons |

2 |

5,213 |

0.38 |

|

Water |

3 |

4,144 |

0.72 |

|

Other* |

4 |

823 |

4.86 |

|

*All four incident releases were emulsions |

|||

_______________________

4 BC Oil Gas Commission, 2018 Pipeline Performance Summary, https://www.bcogc.ca/node/15565/

Pipeline transportation and storage is the safest method for transporting natural gas overland. However, at times it is necessary to use other modes of transport.

Trucking

Natural gas is trucked over highways and roads to various facilities and processing plants. One advantage of trucking is that it allows the natural gas to travel to nearly all destinations with a suitable road, even if there is no nearby port or rail line.

Rail

Moving natural gas by rail is not currently an option. Transporting gas by rail, most likely as cryogenic liquefied natural gas (LNG), is risky. The technology is in its infancy, and so far, tank cars are not permitted to carry fuel on Canadian railroads. However, materials and machinery used by the natural gas industry can be moved by rail and therefore rail transportation does have a role in the industry.

Marine Shipping

Compressed Natural Gas

Compressed natural gas (CNG) is being transported to many parts of the world using specially designed ocean-going ships. ;These ships are used in special cases to move natural gas from deep water ocean drilling platforms to shore based processing and storage facilities; or to move refined gas to markets.They are an alternative to LNG ships where volumes are low, and distances are relatively short. In addition, in coastal areas, barges may be used to transport compressed natural gas to small communities and customer locations to be used, for example at filling stations for CNG-fueled vehicles.

Liquefied Natural Gas

Natural gas is the third largest energy source transported by sea, after oil and coal. The transportation of LNG is one of the most rapidly growing shipping activities. The proposed LNG terminals in British Columbia would be able to accommodate LNG supertankers, which themselves are remarkable examples of engineering. Video 6, below, thoroughly explains these massive ships and the important role they play in the natural gas industry.

Video 6: LNG Super Tanker Engineering Connections BBC Documentary

Video 6 is a very informative and entertaining video with Richard Hammond from Top Gear; and has a lot of useful and informative information about LNG supertankers and the natural gas industry. While you watch it, make a note of any point that you find interesting or confusing or that answers one of the questions that you and your classmates listed in Learning Activity #1. Try to note 10 things by the end of the video.

Gas Storage

Taken together, Canada and the United States have approximately 4.70 trillion cubic feet (Tcf) of working natural gas storage capacity (3.9 Tcf in the US and 0.80 Tcf in Canada). This volume is equal to approximately 60 days of average North American consumption.

In order to quickly access this resource, large quantities need to be stored close to populated areas. Storage methods vary in terms of how easy it is to access the natural gas within them, and by how closely they are or can be located to cities and towns. Some storage methods are naturally occurring; however, their location may be a long distance away from consumers, making it necessary to build storage tanks.

There are four kinds of storage facilities used in Canada for storing natural gas. These are: depleted oil or gas fields, aquifers, salt caverns, and liquid natural gas (LNG) tanks. The first three are discussed here, while the LNG storage tanks are discussed in Module 2.5 Downstream.

Depleted Oil or Gas Fields

Depleted oil or gas fields are the most common type of storage for natural gas.The underground rock formations have already been tapped for recovery of oil or gas. Natural gas can be pumped into the formation by large compressors and stored there until needed. However, the permeability and porosity of the fields is low. This means it takes longer to access and withdraw the gas when needed, in particular when compared to other options such as salt caverns or LNG storage tanks.

Underground Saltwater Aquifer Reservoirs

Aquifer reservoirs are deep, porous and permeable rock formations that have similar geology to oil and gas fields but are filled with saline water instead of oil or gas. In some cases, they can be used for natural gas storage. Gas is injected into the underground rock formation displacing the water that is there. However, aquifers usually require more gas and more monitoring to maintain correct pressure and performance rates.

Salt Caverns

A salt cavern is an underground pool with a thick development of salt formations that is created by mining the salt and injecting gas into the cavern. The porosity and permeability of salt caverns is high, which makes it easier for operators to inject and withdraw gas from them. The ease of inputting and withdrawing the gas makes salt caverns desirable storage facilities when there is lots of demand for gas.

LNG Storage Tanks

Natural gas can be stored above ground in a liquefied natural gas (LNG) storage tank. LNG storage tanks make the gas readily accessible for market and can be used in areas where the terrain is not suitable for underground storage.